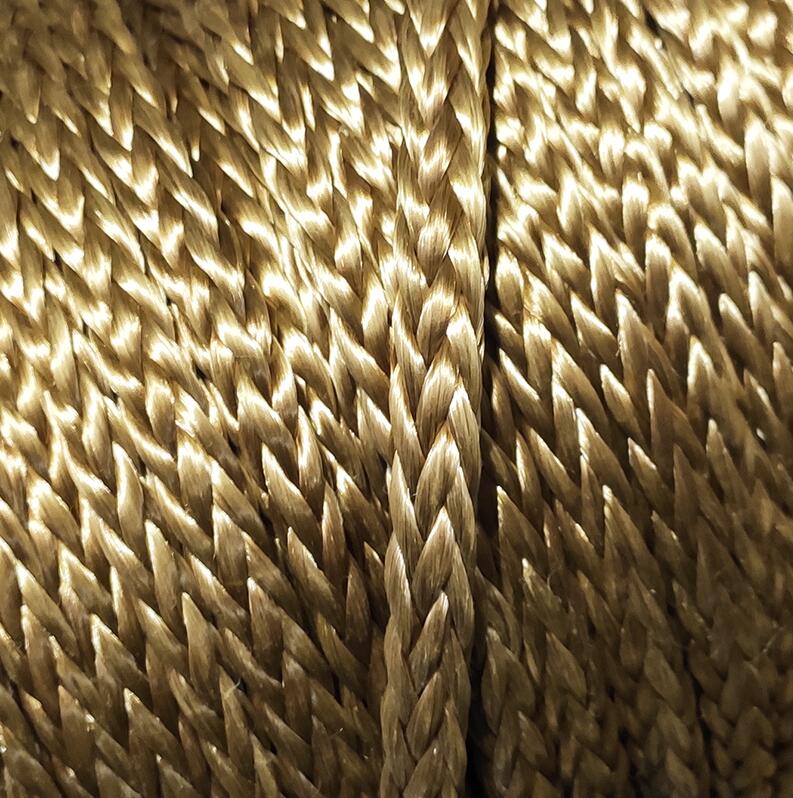

Introduction to the Six Exceptional Properties of Aramid III Fiber Ropes

Aramid fibers are spun from aromatic polyamide resin. They were first successfully developed by DuPont (USA) in 1972. Subsequently, Russia, the Netherlands, Japan, and China also developed high-performance aramid fibers with ballistic resistance.

China classifies aramid fibers as:

Aramid I: Also known as Aramid 14, refers to Poly(p-benzamide) (PBA) fiber.

Aramid II: Also known as Aramid 1414, refers to Poly(p-phenylene terephthalamide) (PPTA) fiber.

Aramid III: Compared to Aramid II, Aramid III has a more complex molecular structure and superior mechanical properties. Aramid III is a ternary copolyamide para-aramid fiber with a heterocyclic structure, formed by the co-polycondensation of three monomers: p-phenylenediamine, terephthaloyl chloride, and a diamine containing a heterocyclic structure, hence the name Aramid III or heterocyclic aramid. The heterocyclic structure of Aramid III gives it ultra-high strength and modulus, along with excellent performance in high-temperature resistance, impact resistance, wear resistance, and wave transmission. It is also more conducive to fiber-resin composite bonding, resulting in superior comprehensive ballistic performance. Furthermore, Aramid III overcomes shortcomings like the poor UV resistance of Aramid II and PBO fibers. It can be said that Aramid III ropes are the batch-produced organic fibers with the best overall performance in the world today.

Aramid III is now widely used in various weapon systems and equipment. It plays a crucial role in promoting the lightweighting, miniaturization, stealth capabilities, and enhanced protection of military equipment, having developed into a key supporting material for modern national defense. Aramid III is a high-performance specialty material that combines structural load-bearing capacity with functionality, possessing inherent excellent properties such as lightweight & high strength, impact resistance, high temperature resistance, flexibility, and abrasion resistance.

1. Heat Resistance and Thermal Aging Resistance

Aramid III ropes exhibit outstanding heat resistance and thermal aging resistance. They decompose only at temperatures reaching 538°C in a nitrogen atmosphere or 520°C in an air atmosphere. When heated to 900°C, Aramid III ropes retain 58% mass residue, undergoing carbonization without melting, demonstrating very good thermal stability. Additionally, Aramid III rope products possess superior resistance to thermal aging compared to imported Aramid 1414 (Kevlar, Twaron).

2. Chemical Resistance

Aramid III ropes are resistant to most chemical substances, offering excellent acid and alkali resistance, as well as resistance to organic solvents, bleaching agents, and protection against insects and mildew. They also exhibit good adhesion to rubber. For example, after treatment in high-temperature acid solution, the breaking strength of Aramid III rope can remain above 80% of the original value, and the elongation at break can remain above 90% of the original. After treatment in high-temperature alkali solution, the breaking strength can remain above 94.5% of the original. Therefore, among the aramid family, Aramid III rope offers the best resistance to high temperatures and acids/alkalis.

3. Mechanical Properties

The mechanical properties of Aramid III ropes rank first among batch-produced organic fibers. The tensile strength of Zhonglan Chenguang's Aramid III ropes ranges from 4400 to 5500 MPa, which is 30% to 50% higher than Aramid 1414 and exceeds the level of high-strength carbon fiber T700. The dynamic modulus ranges from 150 to 180 GPa, second only to steel wire and carbon fiber. The density is only 1.43-1.45 g/cm³, classifying it as a lightweight, high-strength material, and its composite materials show significant weight reduction effects.

4. Surface Wettability

Aramid III ropes have better surface wettability than Aramid 1414. Due to their smaller water contact angle and the presence of uneven shallow grooves on the surface, which increase the specific surface area, when the resin matrix wets the fiber, it can penetrate into these surface grooves, forming a mechanical 'anchoring' type of bond. Therefore, compared to Aramid 1414, Aramid III ropes can achieve higher mechanical bonding force and stronger physical adsorption via van der Waals forces, which is beneficial for enhancing the interfacial bond strength between the fiber and the resin.

5. Flame Retardancy

Aramid III ropes possess excellent flame retardant characteristics, with a Limiting Oxygen Index (LOI) as high as 42%. Therefore, they will not continue to burn when removed from a flame. They have good anti-flammability, do not support combustion, and do not produce afterburning.

6. Stability

Aramid III ropes can be used for long periods without changing their properties. They offer good moisture resistance and excellent biological stability. In contrast, ordinary aramids have poor moisture resistance, and wet aramids quickly lose their properties. If Aramid III rope is placed in hot water for one month, its strength loss is minimal (strength retention rate is 50%-70% higher than other aramids). Furthermore, Aramid III ropes have good dimensional stability and very low thermal shrinkage. When used at 300-350°C, Aramid III rope fibers show almost no shrinkage; when used at 400-450°C, the shrinkage does not exceed 4%. Simultaneously, Aramid III ropes have very high thermal stability and will not lose their characteristics when used at high temperatures.