Spherical Rubber-Sheathed Spiked Cable for Preventing Snagging in Deep-Sea Rock Crevices

Abstract

This cable relates to specialized cables, specifically a spherical rubber-sheathed spiked cable designed to prevent snagging in deep-sea rock crevices. It comprises a cable and several spherical rubber sheaths arranged on the cable. Each spherical rubber sheath includes a sheath body fixed to the cable via a fixing structure and several spikes arranged on the sheath body. This cable indirectly increases the cable's diameter through the spherical rubber sheaths and their spikes, preventing the cable from being caught in small rock crevices. For larger rock crevices, even if a spherical rubber sheath gets stuck, because the sheath is soft, hollow, and equipped with spikes, it will deform and rotate around the spikes as a pivot point when the cable is retrieved, allowing the cable to break free.

Technical Field

This cable pertains to the field of specialized cables, specifically a spherical rubber-sheathed spiked cable designed to prevent snagging in deep-sea rock crevices.

Background Art

Deep-sea cables are specialized cables used by cargo ships, large vessels for salvage operations, or scientific teams for specific experiments. During use, deep-sea cables are frequently deployed and retrieved, making them prone to getting caught in seabed rock crevices. If a cable becomes snagged on rocks, it can not only hinder task completion but also potentially lead to safety incidents. Therefore, this cable discloses a deep-sea cable designed to prevent snagging in rock crevices, addressing the shortcomings of existing cables.

Detailed Description

[0004] To address the deficiencies in existing technology, a spherical rubber-sheathed spiked cable for preventing snagging in deep-sea rock crevices is provided.

[0005] The technical solution of this cable is as follows:

[0006] The spherical rubber-sheathed spiked cable for preventing snagging in deep-sea rock crevices includes a cable and several spherical rubber sheaths arranged on the cable. The spherical rubber sheaths include a sheath body fixed to the cable via a fixing structure and several spikes arranged on the sheath body.

[0007] The cable is provided with an anti-corrosion coating.

[0008] The fixing structure includes a through threaded hole provided on the sheath body and a fixing sleeve braided together with the cable.

[0009] The sheath body is configured as a hollow structure.

[0010] The sheath body is provided with several ventilation holes.

[0011] The distance between two adjacent spherical rubber sheaths is 40-60 cm.

[0012] The diameter of the sheath body is 2-5 times the diameter of the cable.

[0013] The spikes are configured as solid structures.

[0014] The distance between two adjacent spikes is equal.

[0015] The length of the spikes is 1-2 cm.

[0016] The beneficial effects achieved by this cable are as follows:

[0017] This spherical rubber-sheathed spiked cable for preventing snagging in deep-sea rock crevices indirectly increases the cable's diameter through the spherical rubber sheaths and their spikes, preventing the cable from being caught in small rock crevices. For larger rock crevices, even if a spherical rubber sheath gets stuck, because the sheath is soft, hollow, and equipped with spikes, it will deform and rotate around the spikes as a pivot point when the cable is retrieved, allowing the cable to break free.

Brief Description of Drawings

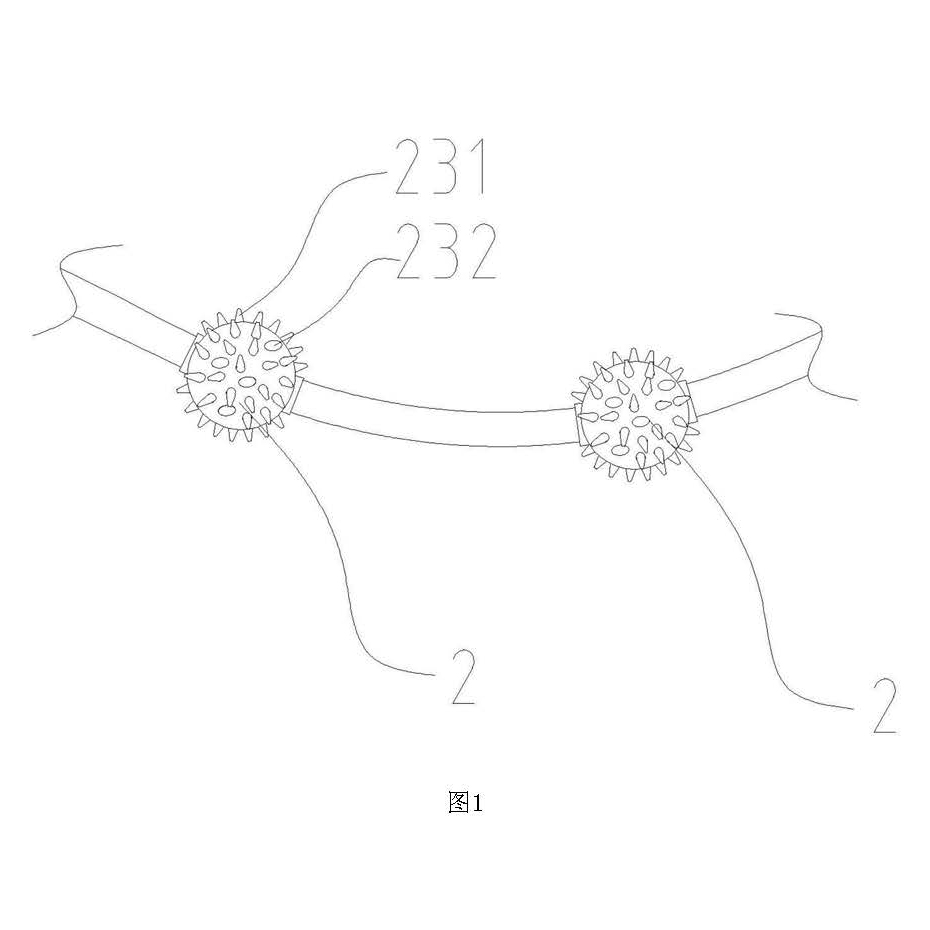

[0018] Figure 1 is a schematic structural diagram of the present invention.

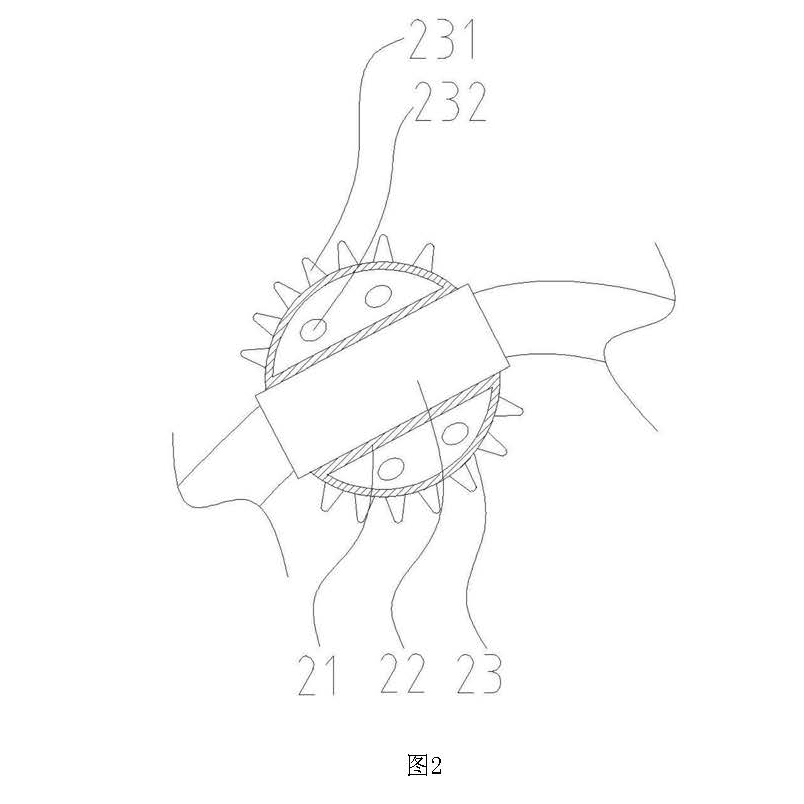

[0019] Figure 2 is a cross-sectional view of the spherical rubber sheath of the present invention.

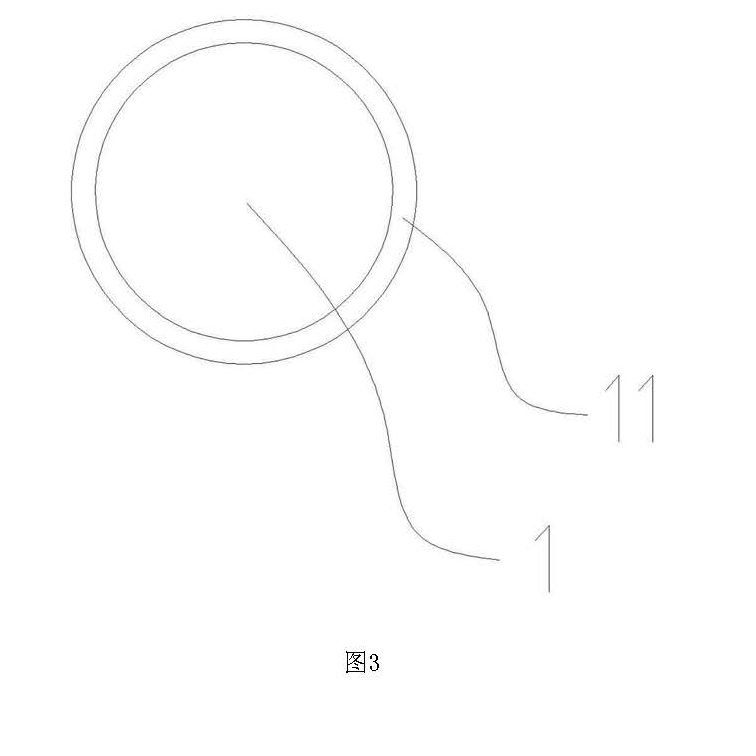

[0020] Figure 3 is a cross-sectional view of the cable.

[0021] In the figures: 1. Cable; 11. Anti-corrosion coating; 2. Spherical rubber sheath; 21. Through threaded hole; 22. Fixing sleeve; 23. Sheath body; 231. Spike; 232. Ventilation hole.

Detailed Implementation

[0022] To facilitate understanding of this cable by those skilled in the art, the specific implementation of this cable is described below with reference to the accompanying drawings.

[0023] As shown in Figures 1-3, a spherical rubber-sheathed spiked cable for preventing snagging in deep-sea rock crevices is provided, comprising a cable 1 and several spherical rubber sheaths 2 arranged on the cable 1. The cable 1 can be a fiber rope or a steel wire rope. The cable 1 is provided with an anti-corrosion coating 11, with a thickness of 0.2 cm, evenly applied to the cable 1, which can significantly increase the corrosion resistance of the cable 1. The spherical rubber sheath 2 includes a sheath body 23 fixed to the cable 1 via a fixing structure and several spikes 231 arranged on the sheath body 23.

[0024] The fixing structure includes a through threaded hole 21 provided on the sheath body 23 and a fixing sleeve 22 braided together with the cable 1. The fixing sleeve 22 can be fixed to the through threaded hole 21 in various ways, such as using threads or adhesive. The primary reason for designing the sheath body 23 and the fixing sleeve 22 separately is to reduce production costs. During production, cables 1 of the same diameter can be manufactured in batches, and different specifications of spherical rubber sheaths 2 can be attached to produce customized deep-sea cables suitable for different seabed rock conditions (as the average width of seabed rock crevices varies in different sea areas), thereby maximizing standardization of the production process and reducing costs.

[0025] The sheath body 23 is configured as a hollow structure and is provided with several ventilation holes 232. When the cable enters seawater, water can flow into the sheath body 23 through the ventilation holes 232. Simultaneously, when the sheath body 23 is compressed, because it is hollow, it can easily deform, and seawater will flow out through the ventilation holes 232. The diameter of the sheath body 23 is 2-5 times the diameter of the cable, and its specific size depends on the seabed rock conditions in the vessel's operating area. Furthermore, the distance between two adjacent spherical rubber sheaths 2 is 40-60 cm, which helps to elevate the marine cable and prevent it from being caught in rock crevices.

[0026] The spikes 231 are configured as solid structures, the distance between two adjacent spikes 231 is equal, and the length of the spikes 231 is 1-2 cm.

[0027] This cable indirectly increases the cable's diameter through the spherical rubber sheaths 2 and their spikes 231, preventing the cable from being caught in small rock crevices. For larger rock crevices, even if a spherical rubber sheath 2 gets stuck, because the sheath is soft, hollow, and equipped with spikes 231, it will deform and rotate around the spikes 231 as pivot points when the cable is retrieved, allowing the cable to break free.

[0028] Furthermore, this spherical rubber-sheathed spiked cable for preventing snagging in deep-sea rock crevices can also be used in combination with ordinary cables to further reduce costs. The ordinary marine cable floats in seawater, while this specialized cable is only used on the end portion of the ordinary marine cable that might come into contact with the seabed rocks.